In today’s rapidly evolving technological landscape, miniaturized electronics have become indispensable, driving innovation across industries. As a company specializing in comprehensive design and manufacturing services for custom, miniaturized electronic modules, ISI understands the crucial role these modules play in advancing technology.

Enter your email to get a summary of our Miniaturization case study.

Our PCB designers tackle the challenge of miniaturizing circuitry for smaller modular electronic components through a strategic approach. They begin by understanding the system requirements and collaborating with our customers to define design goals.

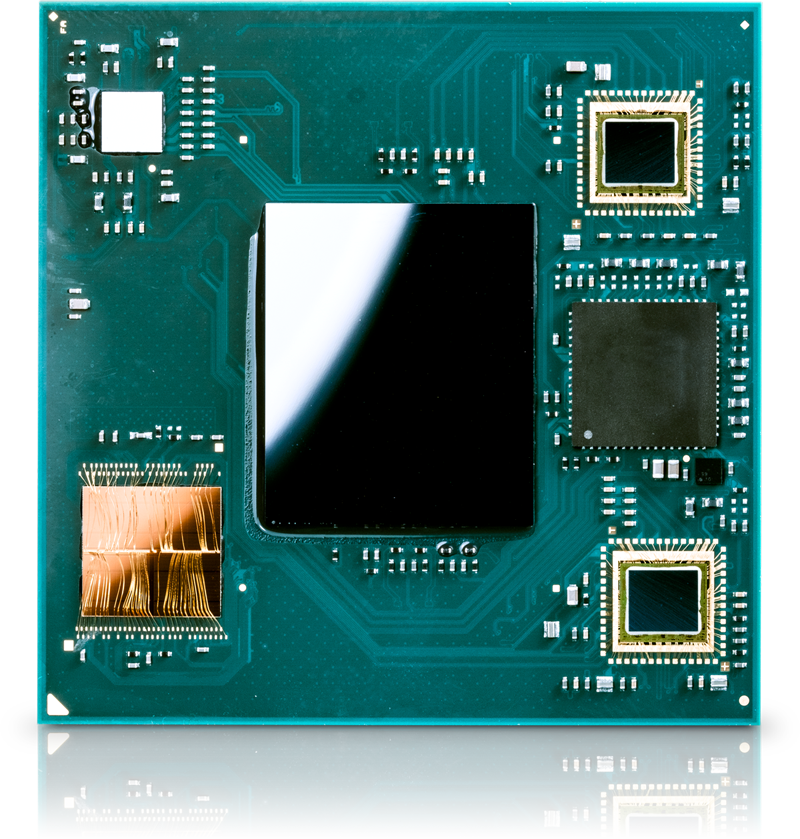

To achieve miniaturization, our designers use surface mount technology (SMT) and high-density interconnect (HDI) PCB designs, enabling a higher component density and better space utilization. Maintaining signal integrity is crucial, and they employ controlled impedance routing and differential pairs to minimize signal degradation and interference. Effective thermal management is addressed through thermal vias, heat sinks, and component placement.

Additionally, our PCB designers work closely with our manufacturing teams to ensure manufacturability, considering component availability, assembly techniques, and testing. The result is the development of smaller and more efficient modular packaged electronic components that drive innovation across industries.

Industries such as defense and aerospace demand modules that can withstand harsh environmental conditions. Our design and manufacturing processes prioritize ruggedization, incorporating techniques such as overmolding and thermal management to ensure reliability and longevity in challenging operating environments.

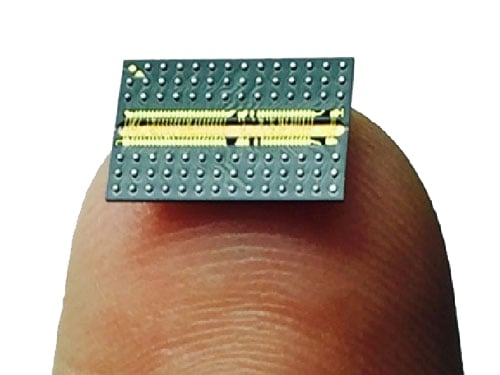

Ultra-dense, SWaP-optimized microelectronic assemblies.

Survive harsh environments;

Temperature cycle, shock, and vibration.

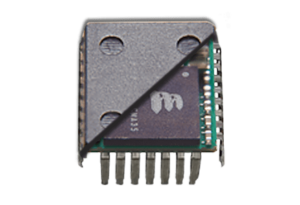

Integration of sensors with microelectronic modules.

Multi-component modules in standard IC form factor

(BGA, QFP, etc.).

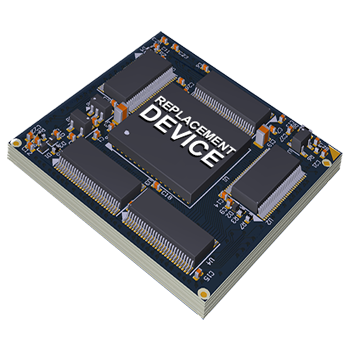

Replace obsolete ICs with a form/fit/function equivalent module.

Your message will go to our in-house technical sales team. We typically get back within one business day.