Home » Resources » Case Studies » Aircraft Engine Control System

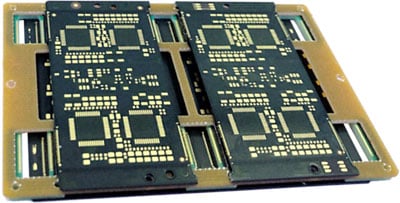

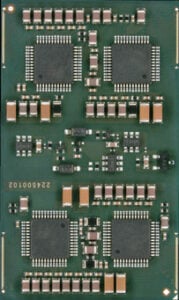

The customer had an aircraft engine control system common to several engine platforms. The control system monitored and controlled RPM, temperature, vibration, cycles, position, and other critical parameters to optimize engine performance. The control system was comprised of several sensor boards and an FPGA central processing board.

The customer elected to consolidate the various boards into a module, which ultimately contained several ADCs, DACs, memory devices and the FPGA processor. The one device allowed them to miniaturize the control system, reduce costs and use the module across several future engine platforms.

Your message will go to our in-house technical sales team. We typically get back within one business day.