Today’s large FPGAs need complex power, clocking, and I/O that consume significant design resources.

Don’t go it alone!

Reduce risk by using our design team—we’ve got the experience from PCB design to firmware. Together with BittWare, we design and manufacture complex microelectronics from PCIe cards down to bare-die ruggedized modules.

As both subsidiaries of Molex, ISI and BittWare share many resources. All BittWare’s PCIe cards are manufactured in the same California facility where ISI’s projects are designed and made. The PCB and firmware design teams at BittWare provide a rich heritage we can bring to your project as needs requirements.

With BittWare, we cover from COTS PCIe to specialized microelectronics modules. If your project's got an FPGA, reach out to us and tap into our broad experience!

From a typical SoM to something much smaller, the size of a SiP, customers find value in our engineering experience.

These projects are where our deep collaborative approach, including offering all the disciplines required in-house, becomes an invaluable asset to tackle the toughest jobs.

BittWare focuses on COTS PCIe form factors with low to medium volumes and high-end FPGAs. This business gives ISI access to a rich ecosystem of FPGA firmware engineers and the related software and support that’s required for customers.

The majority of BittWare cards are also tested and manufactured at the ISI factory in California.

Ruggedization can be applied to these other categories, and ISI has experience with each.

We often give our microelectronics customers unique ruggedization options with our in-house electronics overmolding capabilities.

User customized, turnkey, embedded computing system instruments include an ultra-small form-factor, full-featured PC and supports a wide assortment of XMC or FMC cards. We’ve got experience building solutions for instrumentation, remote, autonomous IO, mobile instrumentation, and distributed data acquisition.

Together with BittWare, our teams have build everything from integrated servers with PCIe cards to complex microelectronics modules.

ISI’s standard and custom connector products and technologies support a wide range of commercial, industrial and defense applications. Our in-house design and manufacturing capabilities allow us to go from concept to production in weeks.

ISI has invested heavily in our bare die assembly equipment and in building a team of skilled bare die assembly and wire bonding technicians. Our extensive bare die handling capabilities allow us to deal with various types of packaging and substrates to deliver complex microelectronics assemblies.

Advanced SMT combined with microelectronics assembly makes ISI a unique manufacturing partner to provide a full, turn-key solution to complex electronic assembly needs.

Encapsulation, or electronics overmolding ensures protection against shock, vibration and harsh environments encountered in subsequent manufacturing processes, as well as throughout the lifetime of the product.

ISI’s broad testing capabilities ensure product quality & reliability. In addition, ISI can develop and implement a comprehensive test plan to verify performance to customer specifications.

Today’s FPGAs can mix RF analog with digital, such as with AMD’s RFSoC devices. BittWare offers these with their RFX-8440 (manufactured by ISI), but customers often want these chips in smaller form factors.

Customers often approach us with an existing SoM they need smaller, and we deliver as a full-service quick-turn design shop. That may include schematic capture, innovative interconnect, or advanced 3D packaging. Because we have such a broad background of designers, capabilities, and projects, we give our customers performance comparisons that get them exactly where they want to be, whether it’s focused on size, speed, or cost.

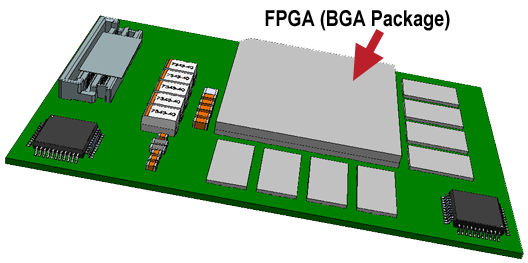

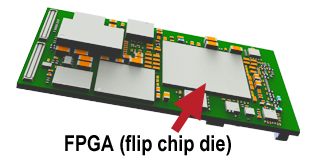

Illustrated is a demonstration of an RFSoC device on a SoM, and how we might use a bare-die version of the chip and a new layout to reduce the module by more than 50%. Need something different? This is just an example of many such microelectronics module projects we’ve produced with FPGAs.

Your message will go to our in-house technical sales team. We typically get back within one business day.