Home » Resources » Case Studies » Custom Interposer with FPGA

A semi-conductor equipment manufacturer was unable to build their equipment due to the long lead-time / unavailability of a FPGA device. The customer located a replacement FPGA device with a much larger footprint, but one that would work in their system. ISI designed a HiLo socket to elevate the replacement device to clear interfering components on the motherboard and fit the device on the existing footprint.

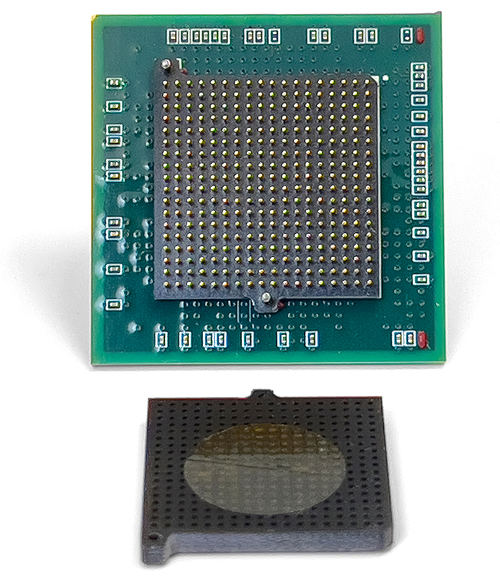

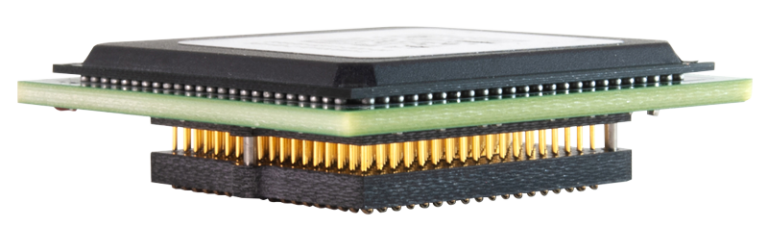

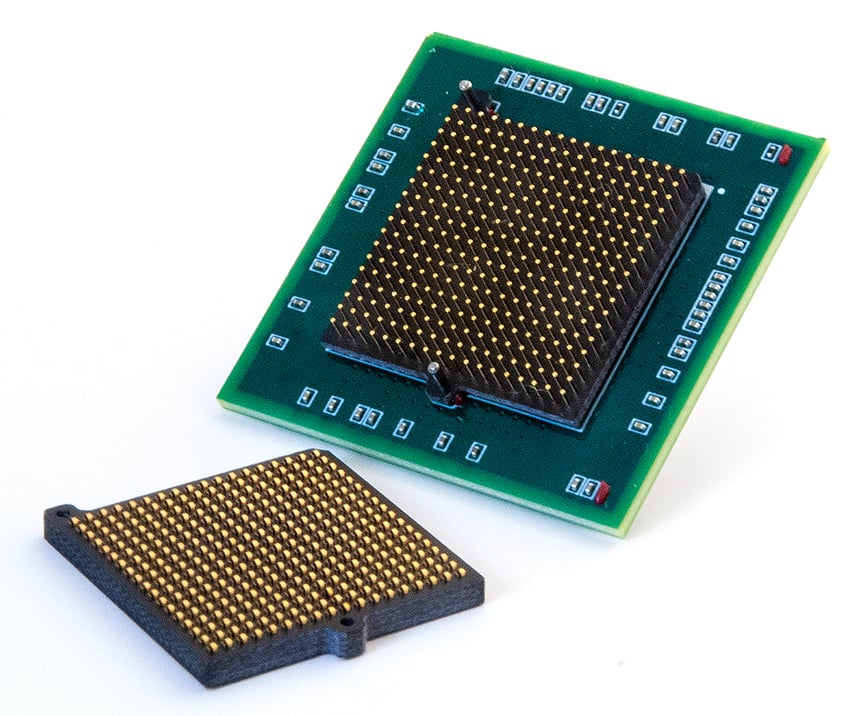

The replacement device consisted of an interposer PCB with an available FPGA device on the top and a HiLo pin field on the bottom. This configuration allowed the customer to fit the replacement FPGA in the existing footprint and allowed them to continue to build their systems.

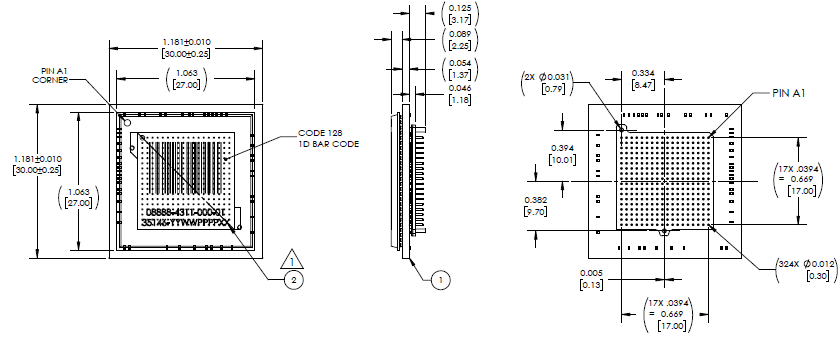

The customer was unable to source FPGAs and was approaching a line-down situation. Their boards were designed for a 19 mm x 19 mm, 324 BGA. They found a 27 mm x 27 mm, 672 BGA which could be adapted.

Tall components close to the 324 BGA footprint interfered with placement of the much larger replacement FPGA as a BGA interposer. ISI’s HiLo connector system was proposed as a solution which raised the interposer above the interfering components. 324 pos SMT HiLo sockets were shipped to the customer in tape and reel and pre-tested 324 pos pinned modules were shipped in trays. The modules were mated with the surface mounted sockets.

ISI collaborated with the customer on board, assembly and test designs, packaging and rework requirements. Socket samples were expedited in one week of customer’s PO allowing the customer to develop their assembly process and initial modules in less than three weeks.

Working with the ISI team is a highly collaborative engagement. The initial requirements customers bring are the starting point, but the big benefit comes as our engineers work to propose various solutions, including pros and cons of each. Those solutions include what many competitors can’t offer, which is in-house execution of nearly all aspects of the project.

Exchange technical details with customer to define challenges and establish scope of the project.

Assess likelihood of achieving the desired outcome and estimate the required engineering effort.

A quote will be issued to include NRE charges, price for prototypes and production volumes, and timeline for completion.

Design work begins with a particular focus on manufacturability. Frequent technical exchanges with the customer ensure a design that meets their expectations.

Upon customer approval, ISI initiates orders with suppliers and starts developing tools, molds, fixtures, and other custom equipment as required.

After satisfactory prototype testing and customer approval, product is released for volume production.

Your message will go to our in-house technical sales team. We typically get back within one business day.