TTI is an authorized distributor of ISI, giving customers access to specialized component services, including IC interposers and BGA reballing.

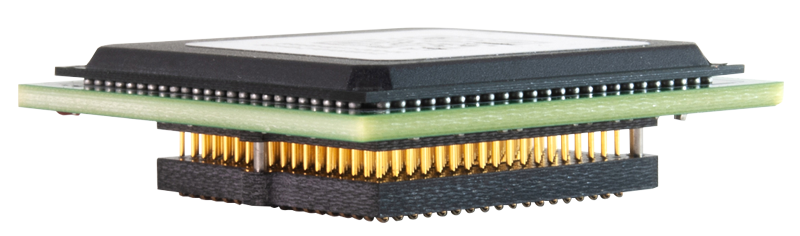

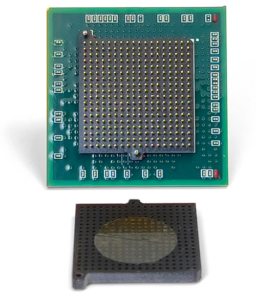

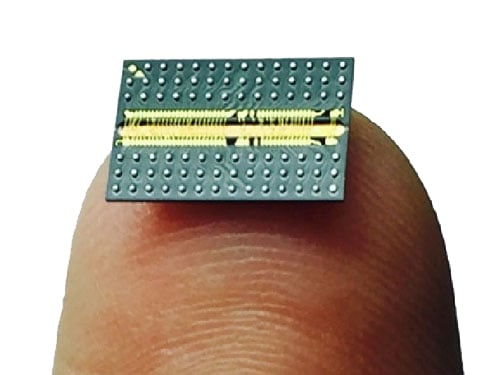

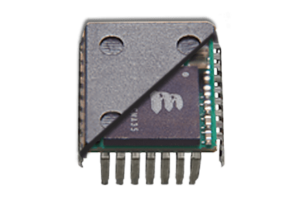

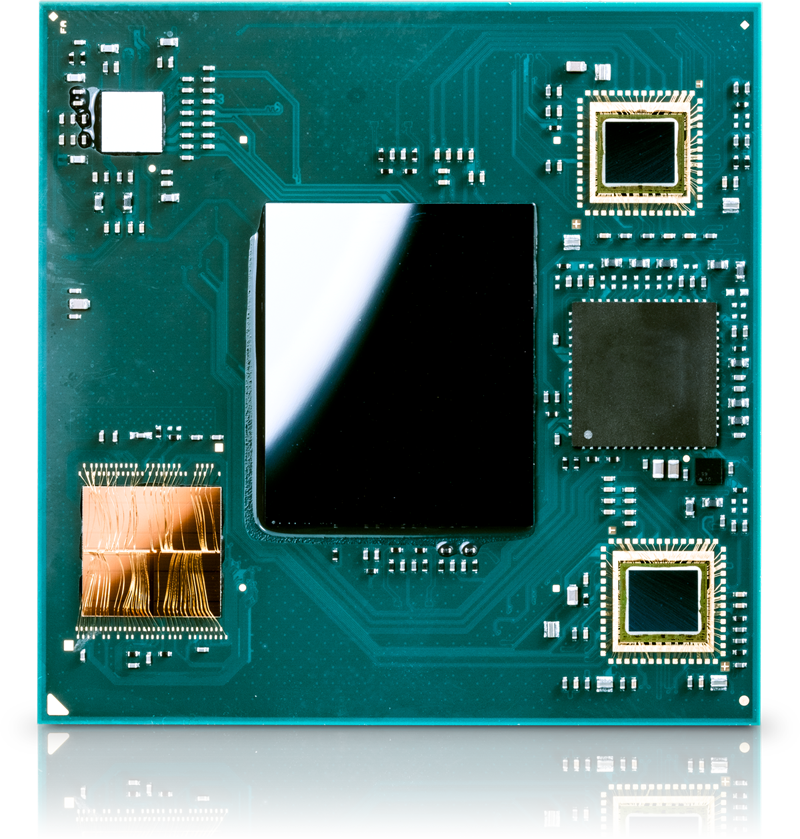

ISI is the industry leader as the world’s largest volume IC manufacturer of IC interposers, designing approximately 150 new interposers each year to help customers through semiconductor shortages, outages, FPGA EOL, FPGA PDN, etc. We can supply the adapter only, as well as provide a complete turn-key assembly by purchasing all the required components, solder the components to the top of the adapter, and test the completed assembly.

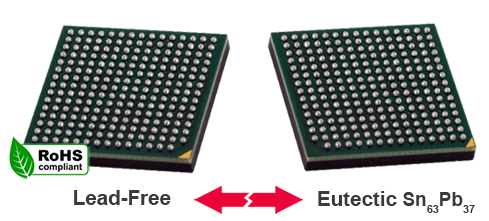

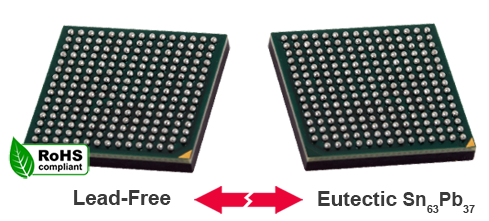

Most semiconductor suppliers have converted to lead-free packaging, creating reliability and compatibility dilemmas for military, aerospace and hi-rel applications. ISI’s process of BGA reballing services involves the removal of lead-free (RoHS) solder spheres then attaching leaded Sn63Pb37 eutectic spheres. ISI offers solutions to meet any customer’s configuration requirements.

Complete this form to provide us with the information we’ll need to evaluate your requirements to estimate project cost and lead time.

"*" indicates required fields

Ultra-dense, SWaP-optimized microelectronic assemblies.

Survive harsh environments;

Temperature cycle, shock, and vibration.

Integration of sensors with microelectronic modules.

Multi-component modules in standard IC form factor

(BGA, QFP, etc.).

Replace obsolete ICs with a form/fit/function equivalent module.