Introducing a technical paper demonstrating an internal study conducted by ISI

Addressing Market Needs to Withstand High Thermal Cycling

Many leading-edge semiconductor device packages are designed for mass-market consumer products, like smartphones, tablets, and wearable technology. While these packages are cost-effective and sufficiently capable for consumer electronics, they are inadequate for harsh environmental applications. For example, leading DDR3 and DDR4 devices are only available in chip-level packages that have demonstrated early-life solder joint failures in environments with frequent temp cycles, including aerospace and defense applications.

Experimental Study Shows Improved Thermal Performance with Overmolding

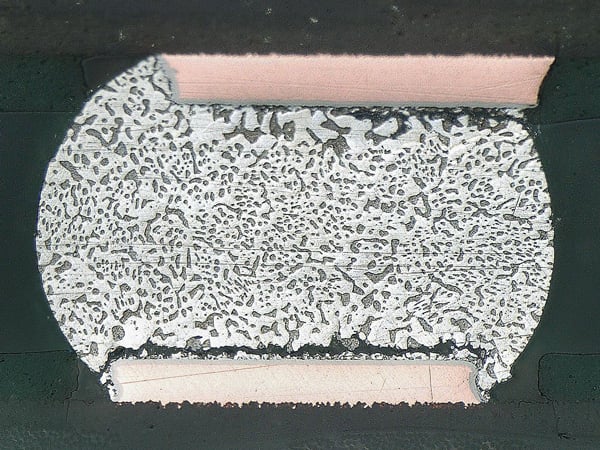

ISI has developed overmolding technology which encapsulates the standard DDR3 device, in material designed to match the CTE of the host motherboard extending solder joint life by 3X over a standard component. This technology is available not just for DDR devices, but any semiconductor chip, as well as multi component modules.

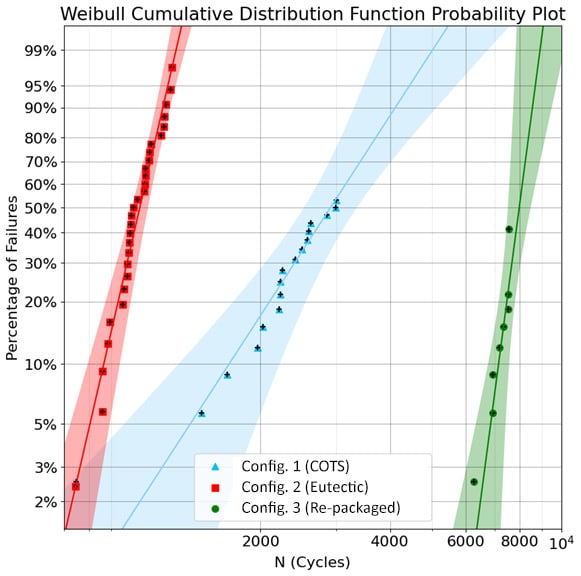

We conducted an experiment to study the effects of thermal cycling on 3 different component configurations (pictured below). Our experiment subjected these configurations to 7,000 continuous one-hour cycles (from -40 C to +95 C to -40 C). The overmolded device (Configuration 3) outperformed the other 2 configurations, resulting in increased solder joint life by a factor of 3x over the standard COTS configuration (Configuration 1). Read our technical paper to learn more about the results of our experiment.

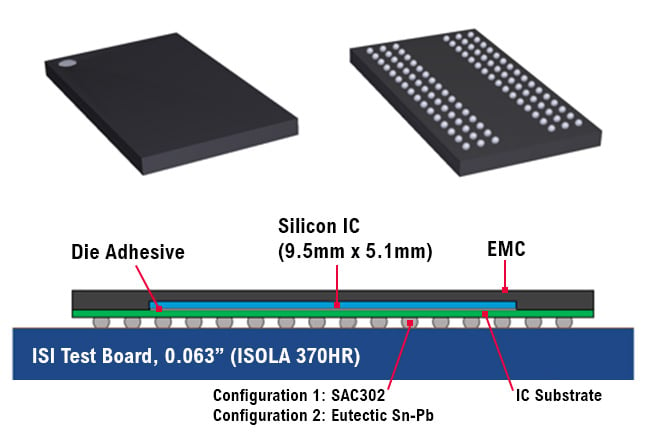

Configurations 1 & 2

Config. 1: COTS Micron component (SAC302 solder balls) and Config. 2: Micron component with SAC302 balls replaced with eutectic tin/lead balls

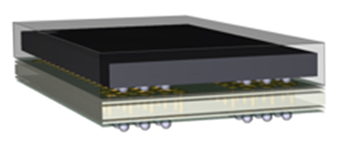

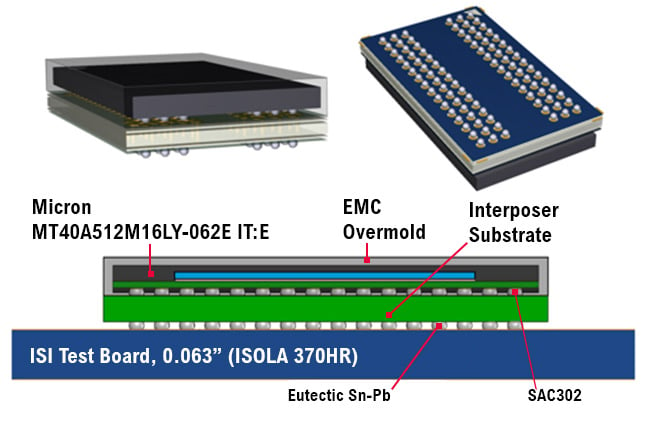

Configuration 3

The COTS Micron part repackaged on an interposer having the same 0.8 mm pitch, eutectic tin/lead balls, and overmolded

In addition to improved solder joint reliability, overmolding provides other benefits, including:

- ISI tests at extended temperatures ensuring the device will perform in the customer’s application

- Finished parts are packaged in tape and reel or JEDEC trays, ready for standard high-volume SMT

- Original footprint is maintained, allowing for use on PCBs designed for standard components

- Our method of overmolding allows for reworkability, unlike underfill

- Ruggedization with an interposer PCB isolates solder balls from device die

Click here for a more in-depth view and to download the PDF,

COTS DRAM Modules Ruggedized with Overmolding for Improved Thermal Cycling Performance